Beschreibung:

“Prepreg ist die englische Kurzform für preimpregnated fibres (amerikanisch: preimpregnated fibers), zu deutsch: „vorimprägnierte Fasern“.” (Quelle: Wikipedia)

Prepreg wird im Motorsport, Sportgerätebau und in der Raumfahrt eingesetzt. Der Grund dafür liegt in der höchstmöglichen Werkstoffperformance und der daraus resultierenden sehr geringen Masse. Für die Verarbeitung ist mindestens ein Ofen in Verbindung mit einer Vakuumpumpe. Optimal wäre ein Autoklav, da dieser zusätzlich Überdruck erzeugen kann. Somit ist nur die Menge an Matrix im Faserverbund die zwingend erforderlich ist.

Nachteilig sind natürlich der Preis des Materials, sowie die Verfügbarkeit der Geräte. Auch benötigen die Oberflächen einiger Nacharbeit.

Prepreg wird für verschiedene Aushärtetemperaturen zur Verfügung gestellt. Low Temperature Prepreg wird meist bei 70 – 80°C gebacken. Herkömmliches meist zwischen 120 – 140°C. High Temperatur Prepreg findet sich bei 180°C und mehr wieder, ist aber besonders kostenintensiv.

Werkzeuge:

- Autoklav

- (Vakuumpumpe + Ofen)

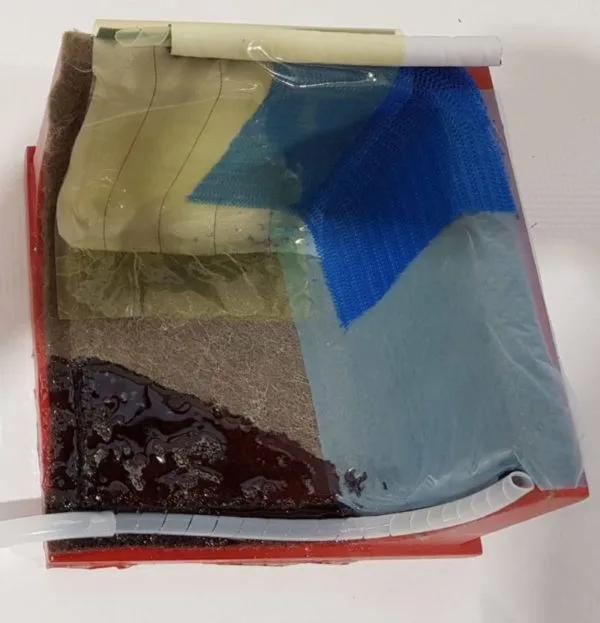

Verbrauchsutensilien:

- Prepreg

- Einweghandschuhe

- Vakuumsack

- Abreißgewebe (Temperaturbeständig)

- Lochfolie (Temperaturbeständig)

- Saugvlies (Temperaturbeständig)

- Dichtband

- Vakuumschlauch (Temperaturbeständig)

- Sprühkleber

Vorgehensweise:

- Aufbringen des Trennmittels auch die Form

- Lagen laminieren (bei Raumtemp. selbstklebend)

- Abreißgewebe mit Sprühkleber besprühen und abbringen

- Vorgang mit Lochfolie und Abreiß gewebe wiederholen

- Vakuumanschluss einbringen

- Vakuumsack groß genug wählen und Verschließen

- Vakuum ziehen

- Temperatur- und Druckverläufe laut Prepreg-Datenblatt einstellen!!!

- Nach Abkühlen der Teile entformen und zu scheiden